ēQATOR takes the first steps towards creating a microwave-heated in-situ mass analyser (MWH ISMA)

- ēQATOR

- Jul 10, 2023

- 2 min read

Updated: Oct 9, 2023

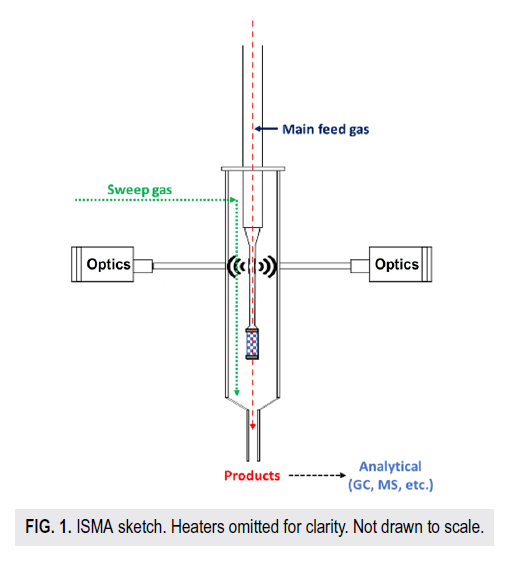

SINTEF with help from MEAM are building a microwave-heated in-situ mass analyser (MWH ISMA) to study kinetics of carbon formation on catalyst formulations under realistic dry reforming conditions. This MWH ISMA will be based on already operational ISMA systems using traditional heating. The image above is a drawing of the MWH ISMA design, a contribution of MEAM.

The ISMA is particularly relevant to sub-second time-resolved studies where mass changes occur due to, e.g., chemical reactions and process conditions such as choice of solid, temperature, gas atmosphere, and pressure. ISMA’s high performance and important improvements in resolution, optics and signal handling, long-term stability at elevated temperature and pressure, user-friendliness, safety, and automatization.

The ISMA concept involves using a vertically oriented tube as an instrument to monitor the mass of a solid sample over time. The tube is fixed at the upper end and allows the sample to oscillate freely at the lower end. By conducting precise frequency measurements and maintaining stable oscillations, the ISMA system enables accurate in situ monitoring of mass changes. The reactor consists of a hollow quartz tube with the sample loaded at the enlarged bottom, tightly screwed to the core body. Oscillation is initiated, and a light-emitting diode (LED) and phototransistor are used to measure the frequency. This frequency signal is processed and used to control a frequency motor, which ensures the oscillation remains at the correct frequency. When the sample conditions change, causing a variation in mass, the oscillating frequency also changes. See below a visual depiction of the ISMA.

Figure source: Karlsson, A., Lødeng, R., Haugholt, K. H., Myhrvold, E., Plassen, M., & Thorshaug, K. (2023).

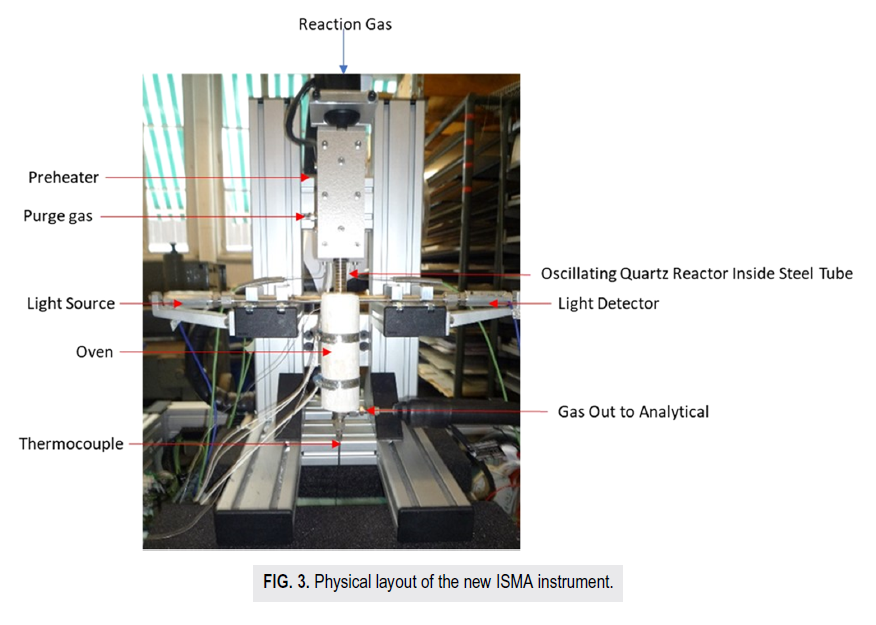

To maintain stable oscillations of the quartz element in the ISMA system (depicted below), the ISMA core is responsible for generating these oscillations. The quartz element offers high performance and stability, even at high temperatures. The overall structure of the vibrating system, including the reactor and heating system, will be redesigned.

The MWH ISMA is designed as a user-friendly, robust, versatile, multi-operator instrument, and will represent an important step beyond the ordinary ISMA systems that use traditional heating.

Figure source: Karlsson, A., Lødeng, R., Haugholt, K. H., Myhrvold, E., Plassen, M., & Thorshaug, K. (2023).

References:

Karlsson, A., Lødeng, R., Haugholt, K. H., Myhrvold, E., Plassen, M., & Thorshaug, K. (2023). High-performance fixed-bed in situ mass analyzer—ISMA. Review of Scientific Instruments, 94(6).

Comments